180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

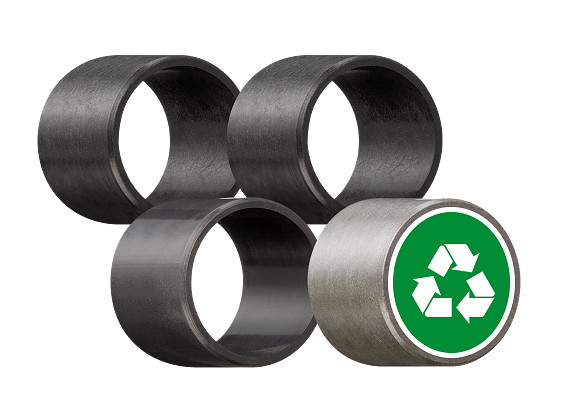

When we first developed high-performance plastics for motion, the topic of environmental protection was admittedly not our main focus. We wanted to develop products that bolstered our clients' manufacturing, improveed technology and reduced costs. Despite this, recycling has always been a sincerely important topic, and we now reuse 99% of our plastic waste by processing it into granulate material and recycling it back into the production process.

Today, we know that products longer lasting products that do not require lubrication contribute to preserving our environment. Eliminating messy, external lubricants means less environmental pollution, less abrasion & less pollution with microplastics, and less weight—meaning less energy required for movement.

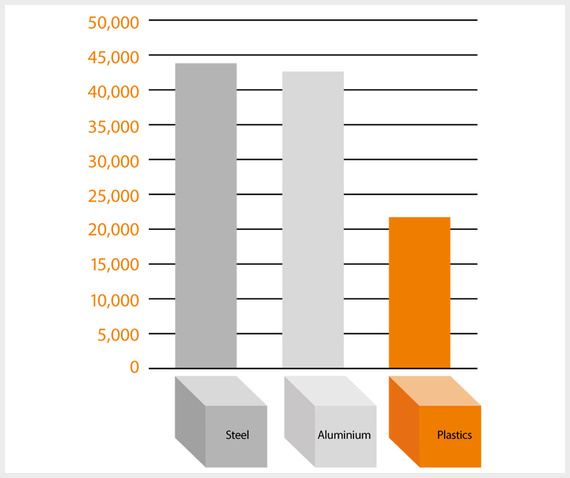

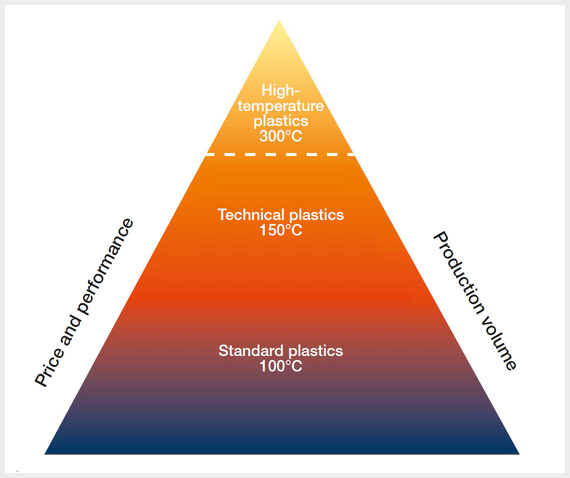

As producers of special plastics, we have clients in many industries as well as the sensitive area of medicine. We are aware of our responsibility to the environment along with the possibilities that plastic offers in many areas compared to steel, and we continue to research new materials and products that will benefit our clients and our environment.

Still to be solved:

Goals:

We are working hard not only to measure and make transparent the CO2 footprint of every component we sell, but also to consistently reduce it. As a first step, we show the CO2 footprint of each plain bearing of our best-selling materials in our web shop.

27 million tons of grease pollute the worldwide environment every year. Our polymers do not require lubrication.