180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

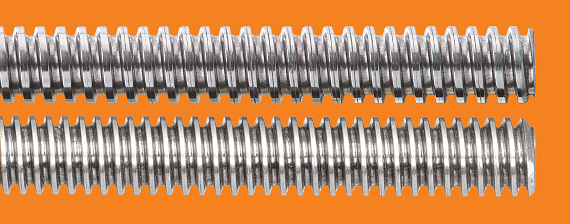

ACME lead screws are a type of threaded rod designed as an alternative to square lead screw threads. They have a trapezoidal thread profile with a wide, flat crest and a steep pitch angle, which increases load-carrying capacity and enhances their efficiency in power transmission.

Compared to lead screws with square threads, ACME screws offer greater load-bearing capabilities, reduced friction, and improved self-locking properties. They’re often used in heavy-duty machinery and high-load systems due to their durability and precision.

Trapezoidal lead screws, while nearly identical to ACME screws, are not quite the same. They both use the same thread profile, but trapezoidal screws use a 30-degree flank angle rather than the 29-degree angle found in ACME screws. However, in certain applications the two formats can be used interchangeably.

igus® is your one-stop shop for all lead screw types, including ACME, trapezoidal, and metric threads, as well as a proprietary high helix design known as dryspin®.

A: An ACME lead screw is a lead screw designed around imperial dimensions that is commonly used to convert the rotary motion of a motor, or hand wheel, into linear motion. They are typically used to drive linear bearings.

A: igus offers single-start ACME screws. This means there is one continuous thread that runs the entire length of the screw.

A: While almost identical there are minor differences. The main difference is that ACME screws are designed around imperial dimensions, whereas Trapezoidal screws are metric. The thread flank angles are also slightly different: ACME screws have a 20-degree angle while Trapezoidal screws are 30-degrees. These two types of screws can be used for the same applications, the primary difference being the designer's preference on units of measure.

A: ACME screws are made with a single-start whereas high helix are composed of multiple starts with higher lead angles. As a result, high helix screws are able to move at higher linear feed rates and lower RPMs than a single start screw. Conversely, the single-start screws are able to move higher loads with less torque. This higher efficiency also means that high helix screws can backdrive, where ACME screws are self-locking — each has its own advantage depending on the application, but a brake mechanism may be required on high-helix setups, particularly in vertical orientations.

A: 304 stainless steel is the material igus offers as standard. Carbon screws are available but may corrode without oil or grease, and igus lead screw nuts are designed to run without external lubrication.

A: Yes, igus has a full line of motors (stepper/BLDC/DC), drive controls, couplings and linear bearings to help you get your project in motion.

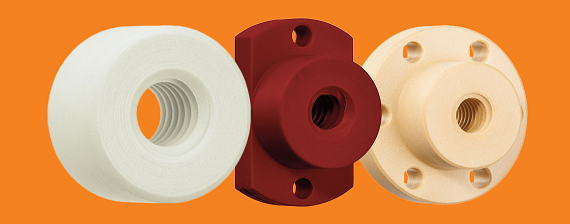

A: Our ACME parts are available in a variety of self-lubricating polymers, each with embedded solid lubricants to eliminate both the need for external lubrication and regular maintenance.

A: ACME screws are stocked standard in 6 foot (1829mm) lengths. Lengths up to 12 feet may be possible.

A: igus offers machining capabilities to include journals, wrench (spanner) flats into ACME screws. We offer bar stock materials as well as SLS printing services for custom nuts. We also offer several injection molding processes for both high and low quantities depending on the customer’s needs.

A: Our ACME nuts are available in a variety of self-lubricating polymers, each with embedded solid lubricants to eliminate both the need for external lubrication and regular maintenance.

A: igus offers ACME 2C, which is referred to as a "centralizing" with a lead accuracy of 0.0007" per every 1" of length. This is the optimal thread class for most power transmission applications. Please note that since the lead screw nuts themselves are plastic, there is no classification other than the clearance being optimized for the temperature range of the material to avoid binding.

Monday to Friday from 8 am - 5 pm

24h