180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

With just a few clicks, the iglide® PRT slewing ring product finder picks the slewing ring bearing suitable for your application and calculates the expected service life.

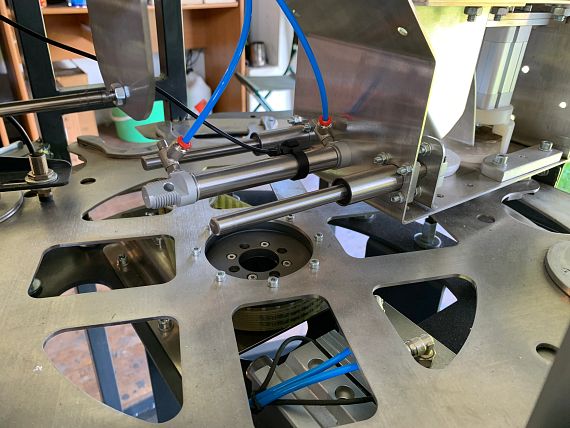

The company GBK Projektowanie i Budowa Maszyn was looking for a way to rotate an assembly table with accuracy. The component sought for should also function without problems in use with dirt and metal debris.

Today, lightweight, robust, self-lubricating polymer bearings are installed in a wide variety of locations in Niles Simmons machine tools and machining centers.

The digital flip chart should smoothly, fluidly and precisely perform a 90 degree rotation to switch between landscape and portrait mode. In order to implement a jolt-free movement in the smallest installation space, a special component was necessary. In addition, the solution should be easy and quick to install.

A: igus® PRT slewing rings are a sliding bearing alternative to the traditional ball bearing slewing ring. They use our iglide® sliding bearing elements, which create a completely maintenance-free solution that is lighter in weight and completely rebuildable.

A: PRTs can be mounted horizontally and vertically, so they are very adaptable. The symmetrical design with bearing liners on both sides means they can also be used overhead.

A: Slewing rings can be mounted in several ways depending on the application; it is best to refer to our assembly instructions and mounting instructions.

A: The PRT-01 is our classic slewing ring bearing. Due to its robust construction, it is characterized by a high torsional strength, and is the most durable PRT. The variety of designs ranges from a stainless-steel version with iglide® F2 sliding elements for ESD conformity, as well as toothed versions to be driven by belts or spur gearing.

The PRT-02 was specifically designed to be lighter weight and more economical. To do this, the series makes use of either plastic outer rings or all plastic rings, with some versions even offering plastic hardware. These could be used in non-magnetic applications such as an x-ray machine. The -02 series will have lower load and tilting movement capacity compared to the -01 series.

The PRT-04 is our newest high-performer in our product range. It is 60% lighter, 50% more compact, and 20% more cost-effective than PRT-01. In addition, we designed this series to be modular and have greatly expanded the available options such as detents, internal toothing, and cleanroom versions. Learn more about all of the different styles by reviewing our PRT-04 series infographic.

A: Yes, of course! We have a few standard catalog stainless steel versions and any PRT system using metal rings can be produced using 316 stainless steel.

A: Customization is possible! If you have a different mounting hole pattern, bolt size requirement or custom feature that needs to be added, please provide us with your drawing/design and we can discuss the requirements together.

A: Yes. An an option, FDA-compliant PRT slewing rings with iglide® A180 plain bearings and stainless steel rings are available.

A: This depends on the size of the slewing ring. The maximum permissible load on one of the largest igus® slewing rings, PRT-01-300, is 33,000 lbs. For the smallest model, PRT-4-00 Micro - for applications with light weight and compact space requirements - the maximum load is 786 lbs statically and 224 lbs during movement.

A: The maximum speed depends on the size. For the largest possible iglide PRT slewing ring, PRT-01-300, this is 50rpm; for the smallest, PRT-01-20, it is 300rpm. As it is a sliding bearing, the surface area of the bearing liners combined with load and speed will have an impact on this.

A: The PRTs' range of tolerance is independent of size, and amounts to 0.25 millimeters both radially and axially.

The axial run-out indicates the maximum height difference for a cycle. It amounts to 0.1 millimeters. The radial run-out indicates the maximum deflection in radial direction during one circulation and amounts to 0.2 millimeters.

A: If the slewing ring will not be hand driven, we offer a few options.

We offer four different gears of the outer ring for our PRT-01 and PRT-04 slewing ring bearings. For a toothed belt drive, you can choose between the conventional toothed belt profiles T10, AT10, or HRD8M. Additionally, a classic spur gearing according to DIN 3967 is available.

For an even more compact design, the PRT-04 is also available with a toothed inner ring according to DIN 3967.

Combine our spur gear version with one of our new iglide® molded gears or have a custom gear 3D printed using our online print service. You can also check out our worm gear joints, which are ready to be directly coupled to motors.

A: Yes, the flatness must be 0.05 millimeters and the surface should have a hardness of at least HBW 50.