180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

180 Bass Pro Mills Drive

Concord

Ontario L4K 0G9

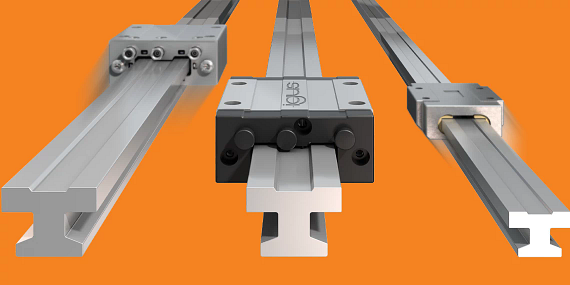

Our drylin® T rails come in hard- and clear-anodized 6060-T66 or 6063T6 aluminum materials. Our carriages are either clear-anodized aluminum, die-cast zinc, or die-cast zinc with e-coat. The liner material options we have are our iglide® J and iglide® J200 materials.

Our drylin® T rails come cut to length per customer specifications to the nearest whole millimeter. Our current standard cutting capabilities hold a tolerance of +/- 2mm. The shortest standard length we can cut in-house is 100mm and up to the maximum length for each profile. The maximum lengths of our drylin® T rails are either 2m, 3m or 4m depending on the profile. If longer lengths are needed, you can butt lengths together following our tech talk instructions.

igus® has the capability to quote custom machining on drylin® T rails. A drawing with tolerances must be provided to igus® to quote custom parts.

igus® has unique online configuration tools to assist in selecting the best system size for your application needs. The configuration tools use thousands of hours of real-world testing data from our test lab in Germany. We provide information including required drive force and safety factors of the system, as well as lifetime expectancy of our liners.

Our carriages come with manual and automatic clearance adjustment options. We also have carriages with the option of hand clamps to lock carriages in place when not being used.

drylin® T is a great option for customers who have the need for zero external lubrication, quiet operation, heavy loads with short strokes, and reduced maintenance. It is a robust system that can handle heavier loads than some of our smaller linear systems while also offering extremely small profiles as well to fit in small, compact spaces.

The manual clearance carriages are adjusted using three different set screws that raise or lower each individual liner inside the carriage. Place the carriage onto the drylin® T rail. An allen key and a wrench are required to adjust the clearance after removing the plastic cap. The wrench unlocks the nut so the allen key can adjust the clearance, then the nut is retightened with the wrench. The automatic clearance carriages are adjusted by placing the carriage onto the drylin® T rail and removing the red keys from the carriage. The clearance will be automatically set and is not able to be adjusted.

Our drylin® T system is interchangeable with some ball bearing systems and some applications. It is always best to check the application parameters either with your local technical sales support, a product specialist, or by using our online configurator. A list of some of the common drop-in replacement solutions can be found above.

Most drylin® T carriage systems are offered with a clearance hole on the bottom or a threaded mounting hole on the top of the carriage for attachment. drylin® T rails should be aligned using the following guide: Aligning Rails 101. Additionally, our carriages have an option for floating carriages to help increase the clearance between the rail and the liners to help with any misalignment of the rails after installation.

Our drylin® T is offered in standard sizes that include 15mm, 20mm, 25mm, and 30mm options with system heights of 24mm (size 15), 30mm (size 25), and 42 (size 30). Our miniature T is offered as small as 7mm with 9mm, 12mm, and 15mm options as well, and system heights of 8mm (size 7), 10mm (size 9), 13mm (size 12), and 16mm (size 15).

drylin® T is typically found in small compact systems like lab automation, medical beds, carts and equipment, and packaging systems.